Objective

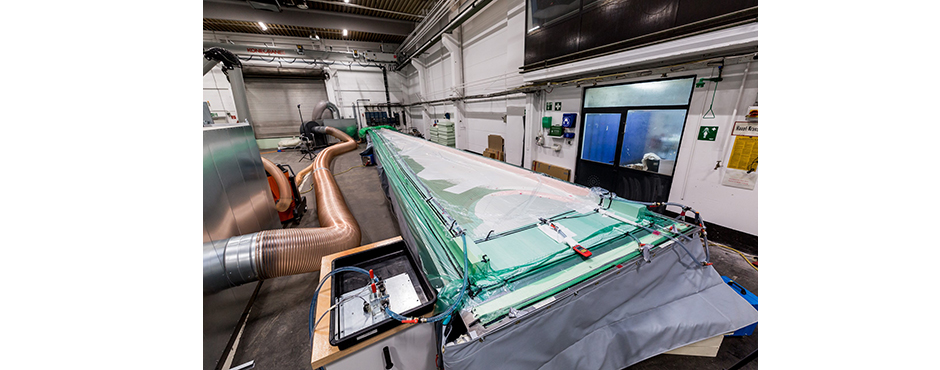

The well controlled and monitored manufacturing of two large scale and additional medium scale blades is a key point in ReliaBlade. This enables the development and validation of material damage models and of sub-component test methodology.

Description of activities and methods

The acquisition of additional information from the manufacturing process is particularly relevant. These data are required for the subsequent analysis and validation steps in other work packages (in particular for the work on the digital twin). The complexity of the whole manufacturing procedure of wind turbine rotor blades and its components, together with the need of transparency of the whole system and easy data mining, makes efficient monitoring of the fiber placement, the infusion and the bonding mandatory.

DTU has focused on the development of characterization techniques and accumulating data on the projects chosen resin system. This has now matured to a stage where the polymers curing schedule can be predicted and tailored to a great extent and allow for optimizing the cure schedule to maximize fatigue performance.

The work packages on manufacturing require composite manufacturing combined with in-process measurement on a high professional level.

Work Package Leaders / Contact

Ingo Gebauer, Christen Malte Markussen